When it comes to manufacturing, engineers and designers are constantly seeking materials that offer an ideal balance between strength, durability, and flexibility. ABS resins, or Acrylonitrile Butadiene Styrene, have emerged as one such solution that meets these requirements and more. In this post, we will delve into the world of ABS resins, exploring their properties, applications, and the reasons behind their popularity in various industries.

About ABS Resins

ABS resins are a thermoplastic polymer blend comprising three distinct monomers: acrylonitrile, butadiene, and styrene. The combination of these monomers imparts unique characteristics to ABS, making it a highly sought-after material in manufacturing. It is worth noting that ABS is considered a copolymer due to its composition of multiple monomers. It is extensively employed in the production of electrical and electronic equipment as well as in the automobile industry.

A Quick Overview of Properties of ABS Resins

The following pointers will help you understand the properties of ABS resins.

- Excellent ductility: ABS possesses good ductility, allowing it to be stretched or bent without fracturing, making it suitable for applications requiring some flexibility.

- High impact strength: Butadiene in ABS improves its impact strength and toughness, thereby making it suitable for products that may experience sudden forces or collisions. The ability to withstand loads and stresses without deformation makes it a suitable choice for structural components.

- Dimensional stability: Even if there are various temperature and environmental conditions, products made from ABS successfully retain their intended dimensions over time. They are proven to retain their shape and structural integrity even under varying temperatures.

- High tensile strength: Due to its high tensile strength, products that are made from ABS are suitable for applications that require weight or tension

- Surface Finish and Color Options: ABS resins can be easily modified to achieve a wide range of surface finishes and colors, providing designers with ample flexibility to meet aesthetic requirements.

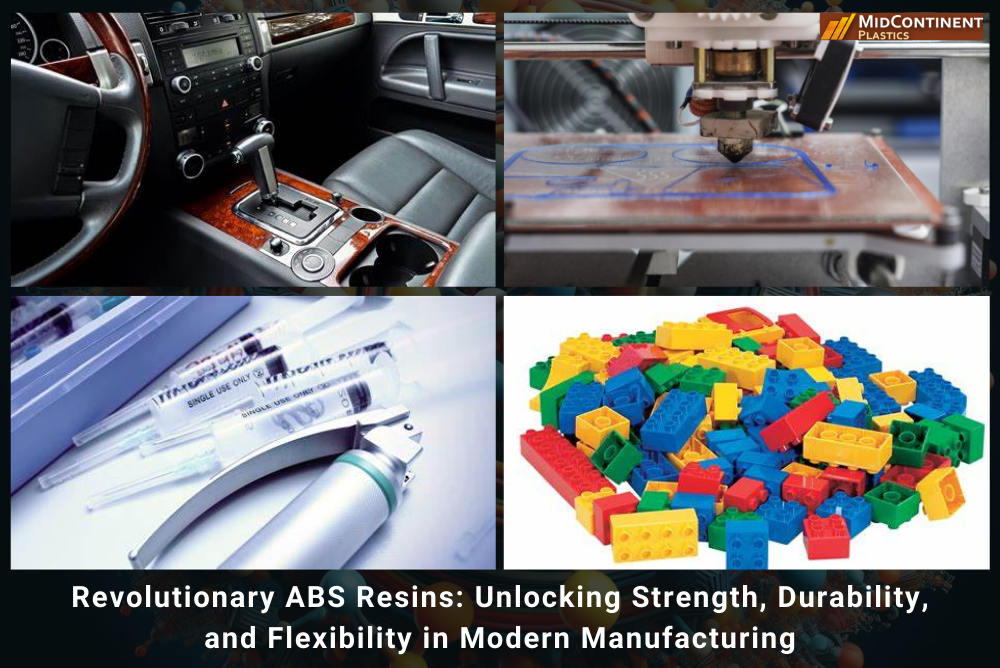

Areas Where ABS Resins Are Used

The following are a few application areas of ABS resins:

- Automotive Industry: These resins find extensive use in the automotive industry where it is used for interior and exterior components. They are used for manufacturing dashboards, door panels, grilles, bumpers, and various other parts due to their excellent impact resistance and durability.

- Electronics and Appliances: ABS resins are widely used in the production of electronic and electrical enclosures, such as computer cases, TV housings, and appliance parts. Their insulating properties, along with resistance to heat and chemicals, make them an ideal choice for such applications.

- Consumer Goods: ABS resins are used in the production of consumer goods due to their versatility. They are used to create toys, kitchenware, luggage, cosmetic containers, and various other products that require a combination of strength, durability, and aesthetic appeal.

- Construction and Architecture: ABS resins play a vital role in the construction and architecture industries. They are utilized for manufacturing pipes, fittings, profiles, and decorative elements. The material’s resistance to chemicals, weathering, and impact makes it an excellent choice for these applications.

- Healthcare and Medical Devices: ABS resins find application in the healthcare sector due to their biocompatibility, durability, and ease of sterilization. They are used in medical device components, including housings for diagnostic equipment, dental models, prosthetics, and enclosures for electronic medical devices.

ABS resins have revolutionized the manufacturing industry with their exceptional properties and versatility. From automotive components to consumer goods and medical devices, there is a strong presence of these ABS resins that have established their presence in various sectors. It is a fact beyond any doubt that with increasing technological advancements, ABS resins are likely to play an even more significant role in shaping the future of manufacturing. Your search for ABS resins is going to end now when you partner with Mid Continent Plastics. The company offers these resins in various volume sizes. Contact the team at Mid Continent Plastics to discuss your requirements.